Refurbishment Heat Exchanger Plate

MOQ : 25 Pieces

Refurbishment Heat Exchanger Plate Specification

- Max. Capacity

- 250 kW

- Thickness

- 0.6 mm

- Max Pressure

- 16 Bar

- Diameter

- 250 mm

- Temperature

- Up to 180C

- Condition

- Refurbished

- Structure

- Plate

- Liquid Flow Rate

- 50-200 m/h

- Weight

- 12 kg

- Dimensions

- 750 mm x 350 mm

- Heat Transfer Area

- 1.2 m²

- Material

- Stainless Steel (SS316/SS304)

- Cleaning Method

- CIP Compatible

- Surface Finish

- Polished

- Application

- Industrial HVAC, Chemical Processing

- Working Pressure

- Up to 10 Bar

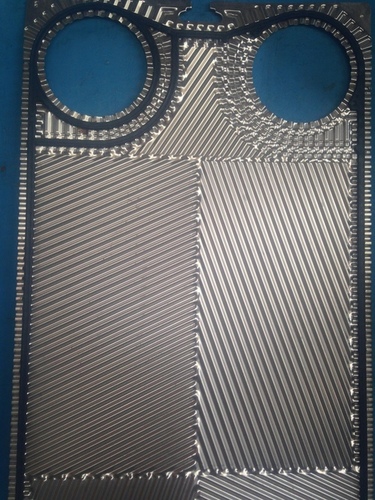

- Plate Type

- Corrugated

- Gasket Material

- EPDM/Silicone

Refurbishment Heat Exchanger Plate Trade Information

- Minimum Order Quantity

- 25 Pieces

- FOB Port

- Vadodara , Gujarat

- Supply Ability

- 300 Pieces Per Day

- Delivery Time

- 2-3 Days

- Sample Available

- Yes

- Packaging Details

- As per products

- Main Domestic Market

- All India

About Refurbishment Heat Exchanger Plate

To provide utmost satisfaction to our clients, we have been engrossed in manufacturing and supplying supreme grade Refurbishment Plate. This plate is manufactured using quality approved components by our experienced professionals at modern production unit. Offered plate is highly cherished among clients owing to its robust construction and optimum strength. Finding application in heat exchangers, provided plate is well suited to be used to transfer heat between two fluids. Apart from this, clients can purchase offered Refurbishment Plate from us in various specifications as per their requirements.

Key Points:

Key Points:

- Corrosion resistant surface

- User-friendly design

- Trouble free functionality

Optimized Heat Transfer Efficiency

With a corrugated plate structure, this heat exchanger maximizes turbulence for superior heat transfer performance. The generous 1.2 m area ensures effective thermal exchange, supporting applications in industrial HVAC and chemical processes. Refurbished under strict standards, it maintains reliability and robust output.

Safe and Reliable Operation

Manufactured from SS316/SS304 stainless steel, the plate handles up to 16 Bar pressure and 180C temperatures. Premium EPDM or Silicone gaskets enhance durability and safeguard against leaks. The polished finish aids hygiene and corrosion resistance, and the refurbished condition guarantees cost-effective service life.

FAQs of Refurbishment Heat Exchanger Plate:

Q: How is the refurbished heat exchanger plate cleaned and maintained?

A: The plate is compatible with CIP (Clean-In-Place) cleaning methods, allowing users to efficiently maintain hygiene without dismantling the system. Routine cleaning ensures optimal heat transfer and extends service life.Q: What benefits does the corrugated plate design offer in industrial usage?

A: Corrugated plates enhance turbulence and surface area, resulting in higher heat transfer efficiency. This design is especially effective for demanding industrial HVAC or chemical processing applications, supporting continuous and reliable operation.Q: When is it appropriate to utilize a refurbished heat exchanger plate versus a new one?

A: Refurbished plates are ideal when seeking reliable performance at reduced cost, provided they meet stringent refurbishment standards. They are suited for projects requiring rapid deployment without compromising quality or capacity.Q: Where can this heat exchanger plate be sourced in India?

A: These plates are available through distributors, exporters, importers, manufacturers, suppliers, traders, wholesalers, and service providers across India, ensuring broad accessibility for industrial clients.Q: What is the process for refurbishing the heat exchanger plate?

A: Refurbishment involves thorough inspection, cleaning, re-polishing, and replacement of gaskets and any compromised components. The process assures that plates reach performance standards comparable to new units.Q: How does the gasket material impact operational safety?

A: EPDM and Silicone gaskets deliver reliable sealing under high temperatures and variable pressures. Their robust chemical resistance prevents leaks and maintains operational safety during intensive industrial processes.Q: What usage parameters should be considered for efficient operation?

A: Ensure the plate operates within the recommended pressure (up to 10 Bar working, 16 Bar maximum), temperature (up to 180C), liquid flow rate (50200 m/h), and capacity (up to 250 kW) to maintain efficiency and avoid premature wear.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Heat Exchanger Spares Parts Category

Industrial Heat Exchanger Plate

Price Range 574.00 - 750.00 INR

Minimum Order Quantity : 10 Sets

Structure : Other, Corrugated stainless steel plate, gasketed design

Max Pressure : 2.5 MPa

Condition : New

Heat Exchanger Gasketed Plate

Price 467000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Structure : Other, Gasketed Plate

Max Pressure : 10 bar

Condition : New

Metal Heat Transfer Plates

Price 465 INR

Minimum Order Quantity : 1 Piece

Structure : Other, Flat and corrugated plate

Max Pressure : 15 bar

Condition : New

PTFE Sealing Ring

Price 68 USD ($)

Minimum Order Quantity : 10 Pieces

Structure : Plate Heat Exchanger

Max Pressure : 3000 m3/hr

Condition : New

|

DIVA ENGINEERING WORK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry