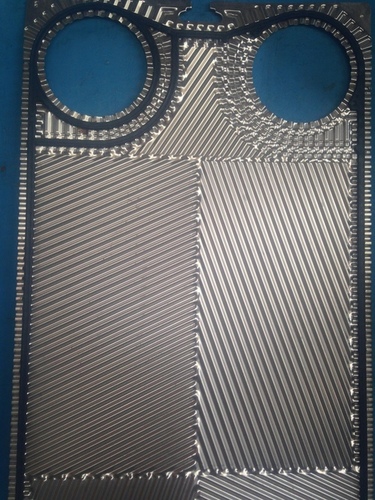

Heat Exchanger Gasketed Plate

Price 467000.00 INR/ Unit

Heat Exchanger Gasketed Plate Specification

- Diameter

- DN50 to DN150 (Inlet/Outlet)

- Temperature

- -10C to 180C

- Number of Pipe

- 4

- Max Pressure

- 10 bar

- Max. Capacity

- 200 kW heat exchange

- Thickness

- 0.6 mm (plate thickness)

- Condition

- New

- Structure

- Gasketed Plate

- Liquid Flow Rate

- Up to 150 m/h

- Working Presssure

- 10 bar

- Voltage

- N/A (Passive Equipment)

- Power

- N/A (Passive Equipment)

- Weight

- 50 kg

- Dimensions

- 1200 mm x 500 mm x 300 mm

- Application

- HVAC, Food Processing, Chemical, Power Stations

- Connection Type

- Flanged or Threaded

- Cleaning

- Easy to disassemble for maintenance

- Frame Material

- Carbon Steel (epoxy coated)

- Heat Transfer Area

- Up to 50 m²

- Plate Material

- Stainless Steel 316L

- Service

- Hot water, chilled water, industrial process fluids

- Gasket Material

- EPDM, NBR, or Viton

Heat Exchanger Gasketed Plate Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Vadodara , Gujarat

- Supply Ability

- 300 Units Per Week

- Delivery Time

- 2-3 Days

- Packaging Details

- As per products

- Main Export Market(s)

- Asia, Africa

- Main Domestic Market

- All India

About Heat Exchanger Gasketed Plate

As a leading firm in this domain, we have been engrossed in manufacturing and supplying quality assured PGasketed Plate Heat Exchanger. This exchanger is ideal for transferring heat between medium and low pressure fluids. Offered exchanger is available in various specifications as per clients demand. Provided exchanger is manufactured using top notch grade components under guidance of our dexterous professionals at well-equipped production unit. Moreover, offered Gasketed Plate Heat Exchanger is tested on various quality parameters to ensure its durability.

Key Points:

- Flawless functionality

- Simple to operate

- Robust construction

Versatile Application and Robust Design

Suitable for demanding environments like HVAC systems, food processing plants, and industrial fluid transfer, this heat exchanger delivers efficient heat management. Its stainless steel 316L plates guarantee resilience against corrosion and high temperatures, ensuring long service life even with aggressive media. The gasket options (EPDM, NBR, Viton) accommodate a wide range of fluids and temperatures.

Effortless Maintenance for Optimal Performance

With a gasketed plate structure and user-friendly assembly, the unit can be disassembled rapidly, streamlining both scheduled and emergency maintenance. This design ensures consistent operational efficiency, minimizes downtime, and supports rigorous hygiene standards, which is vital in sensitive applications such as food and pharmaceuticals.

FAQs of Heat Exchanger Gasketed Plate:

Q: How does the gasketed plate heat exchanger enhance heat transfer efficiency?

A: The gasketed plate heat exchanger uses multiple thin stainless steel 316L plates arranged to maximize heat transfer surface area while minimizing energy loss. This design allows efficient transfer between hot and cold fluids even at high flow rates, up to 150 m/h, ensuring optimal energy utilization in HVAC, food processing, or industrial operations.Q: What types of applications are suitable for this heat exchanger?

A: This heat exchanger is ideally suited for HVAC systems, food processing, chemical plants, power stations, and any industrial process requiring robust heat management with reliable temperature and pressure ratings. Its versatility extends to hot/chilled water and various industrial fluids, supporting heat exchange capacities up to 200 kW.Q: When should maintenance or gasket replacement be performed on this unit?

A: Maintenance should be carried out according to your operational schedule or when flow rates decrease or leaks are detected. Regular inspection and prompt replacement of worn EPDM, NBR, or Viton gaskets ensure consistent sealing and performance, particularly in demanding environments with temperature fluctuations.Q: Where can this heat exchanger be installed?

A: Due to its compact dimensions (1200 mm x 500 mm x 300 mm) and customizable connection types (flanged or threaded, DN50DN150), installation is flexible and suitable for mechanical rooms, process plants or industrial sites with limited space. Its robust frame ensures stability even in challenging environments.Q: What is the process for cleaning and maintaining the heat exchanger?

A: To clean the unit, simply disassemble the modular frame and remove the plates for inspection and cleaningno special tools are required. The accessible design enables thorough removal of deposit build-up, prolonging service life and maintaining efficient operation in all applications.Q: How does the choice of gasket material benefit different applications?

A: EPDM is well-suited for hot water and mild chemicals, NBR excels in oil-resistant environments, and Viton offers exceptional performance with aggressive chemicals and higher temperatures. Selecting the appropriate gasket material optimizes compatibility and extends the operational lifespan of the heat exchanger.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heat Exchanger Spares Parts Category

Heat Exchanger Cleaning Plate

Price 4800.00 INR / Unit

Minimum Order Quantity : 1 Set

Temperature : Other, Max 180C

Condition : New

Structure : Plate Heat Exchanger

Thickness : 2 mm

Heat Exchanger Custom Plate

Price 574 INR / Unit

Minimum Order Quantity : 1 Unit

Temperature : Other, Up to 180C

Condition : New

Structure : Plate Heat Exchanger

Thickness : Varies from 0.5mm to 1.0mm

Refurbishment Heat Exchanger Plate

Price 375 INR

Minimum Order Quantity : 25 Pieces

Temperature : Other, Up to 180C

Condition : Other, Refurbished

Structure : Other, Plate

Thickness : 0.6 mm

Heat Exchanger Stainless Steel Plate

Price 162000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Temperature : Hightemperature

|

DIVA ENGINEERING WORK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry