Shell and Tube Heat Exchanger

MOQ : 1 Piece

Shell and Tube Heat Exchanger Specification

- Max. Capacity

- 25,000 kcal/hr

- Thickness

- 8 mm shell thickness

- Temperature

- Maximum 200C

- Diameter

- 400 mm

- Max Pressure

- 16 bar

- Condition

- New

- Structure

- Horizontal

- Liquid Flow Rate

- 2500 LPH

- Weight

- Approx. 300 kg

- Dimensions

- 2000 mm (L) x 400 mm (D)

- Application

- Chemical, Pharmaceutical, Food Processing

- Material

- Stainless Steel (SS304/316)

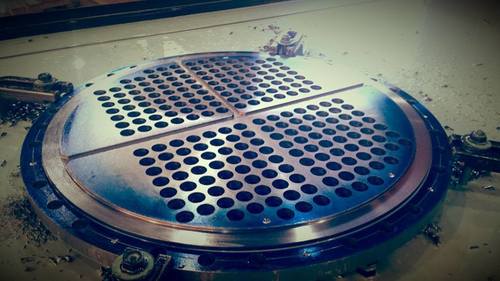

- Number of Pipe

- 80 tubes

- Design Standard

- ASME/TEMA

- Tube Length

- 1800 mm

- End Connections

- Flanged Ends

- Corrosion Resistance

- High

- Tube Sheet Material

- Stainless Steel

- Installation Orientation

- Horizontal/Vertical

- Shell Material

- Stainless Steel

- Maintenance

- Easy to Clean

- Heat Transfer Area

- 6.5 m²

- Working Pressure

- 10 bar

- Tube Diameter

- 19 mm

- Leak Test

- Hydrostatic Pressure Test

- Baffles

- Segmental type

Shell and Tube Heat Exchanger Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Vadodara , Gujarat

- Supply Ability

- 300 Pieces Per Day

- Delivery Time

- 2-3 Week

- Packaging Details

- As per products

- Main Domestic Market

- All India

About Shell and Tube Heat Exchanger

Incorporated in year 1979, we have been engaged in manufacturing and supplying a huge range of Shell and Tube Heat Exchanger Assembly. Offered assembly is used for filling space between high temperature applications like heat exchanger. Provided assembly is manufactured using quality assured components under guidance of our deft professionals at highly advanced production unit. Provided assembly is highly demanded in industrial and commercial places. Apart from this, offered Shell & Tube Heat Exchanger Assembly can be purchased from us at affordable rates.

Key Points:

Come to us for quality no cheper service will attended by team diva executives.

Based on our reputed AMC clientele moral outlook and industry experience with our service unit.

Key Points:

- Robust construction

- Excellent strength

- Rust resistant surface

Come to us for quality no cheper service will attended by team diva executives.

Based on our reputed AMC clientele moral outlook and industry experience with our service unit.

High-Efficiency Thermal Performance

With a heat transfer area of 6.5 m and a maximum capacity of 25,000 kcal/hr, this exchanger delivers optimal energy efficiency for demanding industrial applications. The segmental baffle construction ensures fluid turbulence, enhancing heat transfer rates and maintaining consistent thermal profiles, even under high flow rates of up to 2500 LPH.

Robust Stainless Steel Construction

Manufactured from SS304/316 stainless steel for the shell, tubes, and tube sheets, this unit offers superior resistance against corrosion and chemical attack. Its 8 mm shell thickness and flanged end connections guarantee rugged operation, longevity, and safety in aggressive work environments, including chemical, pharmaceutical, and food sectors.

Flexible Installation and Easy Maintenance

Designed for both horizontal and vertical orientations, this shell and tube exchanger adapts to various plant layouts. The structure allows straightforward access for cleaning and inspection, reducing downtime and ensuring uninterrupted operation, which is critical in continuous production facilities.

FAQs of Shell and Tube Heat Exchanger:

Q: How is the Shell and Tube Heat Exchanger installed in an industrial setting?

A: Installation is versatile and can be performed in either horizontal or vertical orientation to suit plant layouts. Flanged end connections enable secure and straightforward integration into piping systems, and the units dimensions (2000 mm L x 400 mm D) fit most standard industrial spaces.Q: What makes this heat exchanger suitable for the chemical, pharmaceutical, and food industries?

A: Its high corrosion resistance, robust stainless steel (SS304/316) construction, and adherence to ASME/TEMA standards ensure safety and longevity when handling aggressive or sensitive media. The easy-to-clean design supports sanitary requirements for food and pharmaceutical production.Q: When is cleaning or maintenance required for this exchanger?

A: Routine maintenance should be performed based on operational load and media, but its accessible construction allows for quick cleaning during scheduled downtime, helping maintain optimal heat transfer efficiency and extend service life.Q: Where is this type of heat exchanger commonly installed?

A: Its frequently installed in chemical processing, pharmaceutical manufacturing, and food production facilities across India, thanks to its robust corrosion resistance, easy integration, and proven thermal performance.Q: What is the process for leak testing the heat exchanger?

A: The exchanger undergoes hydrostatic pressure testing to ensure airtightness and structural integrity before dispatch. This process verifies that it can withstand working pressures up to 16 bar, aligning with industry standards and safety regulations.Q: How does the segmental baffle design benefit heat transfer efficiency?

A: Segmental baffles induce controlled turbulence and direct fluid flow effectively over the tube bundle, enhancing the exchange process by increasing fluid velocity and improving overall heat transfer rates.Q: What are the main usage benefits of choosing stainless steel SS304/316 material for this heat exchanger?

A: SS304/316 provides high resistance to corrosion, chemical attack, and thermal stress, making the unit durable under rigorous conditions. This leads to lower maintenance costs, longer service life, and reliable performance in critical industrial applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Welded Heat Exchanger Category

Condenser Evaporator Tube Exchanger

Price 12080 INR

Minimum Order Quantity : 1 Piece

Liquid Flow Rate : 1.2 m/h

Working Presssure : 1.5 MPa

Condition : New

Shell Tube heat Exchanger

Price Range 574.00 - 750.00 INR

Minimum Order Quantity : 1 Unit

Liquid Flow Rate : 02500 Cubic m/s

Working Presssure : 0250

Condition : New

|

DIVA ENGINEERING WORK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry