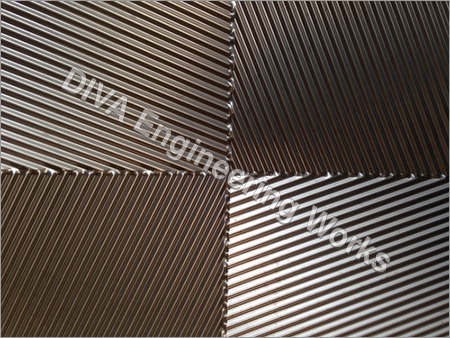

Heat Exchanger Pasteurization Plate

Price 1 INR/ Unit

Heat Exchanger Pasteurization Plate Specification

- Thickness

- 0.6 mm

- Temperature

- 85C 90C

- Diameter

- 32 mm

- Max. Capacity

- 1000 L/h

- Max Pressure

- 1.0 MPa

- Condition

- New

- Structure

- Plate Type

- Liquid Flow Rate

- 1 10 m/h

- Working Presssure

- 0.6 MPa

- Voltage

- 220/380 V

- Power

- 2.2 kW

- Weight

- 280 kg

- Dimensions

- 1200 x 600 x 1500 mm

- Surface Finish

- Polished

- Heat Transfer Area

- 8 m²

- Port Connection

- Flanged/Clamped

- Material

- Stainless Steel 304/316

- Cleaning Type

- CIP (Clean-in-Place)

- Heat Exchanger Type

- Gasketed Plate

- Control Type

- Automatic/Manual

- Usage/Application

- Milk, Juice, Beverage Pasteurization

Heat Exchanger Pasteurization Plate Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Vadodara , Gujarat

- Supply Ability

- 300 Units Per Day

- Delivery Time

- 2-3 Days

- Packaging Details

- As per products

- Main Export Market(s)

- Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, North America, Australia

- Main Domestic Market

- All India

- Certifications

- Shell & Tube, Heat Recovery, Plate, Welded - Semi welded Primary Exchanger Material Hast-Alloy diff. Graded, Steel, Titanium Brand Diva Alfa Laval HRS APV Funke et Application Pharmaceutical industry, Food Process Industry, Hydraulic and Industrial Process, Chemical, Milk & Pasturier, Medical, Power Generation Warranty 18 months, 12 months Tube Material Steel, Titanium, Copper Inlet Temperature 170 Outlet Temperature 32,10 Flow Rate (L/min) DIN 10,up to DIN 500 Maximum Working Pressure (in PSI) 25 bar or more Dimension Variant Size Variable

About Heat Exchanger Pasteurization Plate

We offer the best qualityPasteurization Plate Heat Exchangerfor the use in heat management setup. The plates are made with durable quality, tested material with the use of latest engineering applications to shape the best possible product. We are the renowned manufacturer and supplier of a wide range of heat exchanging equipments. The product is tested and certified on various quality and endurance parameters. ThePasteurization Plate Heat Exchangeris available at a very reasonable price.

Main Features:

- Durable and high temperature endurance

- Corrosion resistant

- Easy and quick installation

Shell & Tube, Heat Recovery, Plate, Welded - Semi welded

Primary Exchanger Material Hast-Alloy diff. Graded, Steel, Titanium

Brand Diva Alfa Laval HRS APV Funke et

Application Pharmaceutical industry, Food Process Industry, Hydraulic and Industrial Process, Chemical, Milk & Pasturier, Medical, Power Generation

Warranty 18 months, 12 months

Tube Material Steel, Titanium, Copper

Inlet Temperature 170

Outlet Temperature 32,10

Flow Rate (L/min) DIN 10,up to DIN 500

Maximum Working Pressure (in PSI) 25 bar or more

Dimension Variant

Size Variable

Superior Heat Transfer for Reliable Pasteurization

Utilizing an 8 m heat transfer area, this heat exchanger ensures efficient and consistent thermal processing of dairy and beverage products. Crafted from polished stainless steel 304/316, it resists corrosion and guarantees hygiene in demanding environments, reducing contamination risks during pasteurization.

Versatile Operation and User-Friendly Control

The system can operate under automatic or manual control, adapting to various production needs. Its gasketed plate structure and flanged/clamped connections enable quick adjustments and easy maintenance, simplifying integration within existing production lines for milk, juice, or beverage processing.

Optimized Cleaning and Maintenance

Incorporating CIP (Clean-in-Place) technology, the unit streamlines routine sanitation without dismantling. This process efficiently removes residue and maintains hygiene standards, minimizing downtime and enhancing operational efficiency for manufacturers and service providers.

FAQs of Heat Exchanger Pasteurization Plate:

Q: How does the heat exchanger pasteurization plate maintain optimal temperature for milk, juice, and beverage processing?

A: The unit utilizes stainless steel 304/316 plates with an 8 m heat transfer area, efficiently transferring heat to maintain pasteurization temperatures between 85C and 90C. This precise control ensures that products are safely pasteurized without compromising quality.Q: What materials make up the plate structure and why are they chosen?

A: The plate structure is constructed from stainless steel 304/316. These materials are selected for their corrosion resistance, sanitary properties, and ability to withstand high temperatures and pressure, making them ideal for food and beverage pasteurization.Q: When should the Clean-in-Place (CIP) process be performed for the system?

A: CIP cleaning should be conducted after each production cycle or as required by your hygiene protocols. This automated cleaning process ensures all internal surfaces of the heat exchanger remain free of microbiological contamination and residue.Q: Where is this pasteurization plate suitable for installation?

A: This unit is ideal for installation in dairy plants, juice factories, beverage processing facilities, or any location requiring hygienic, automated, or manual pasteurization. Its compact dimensions (1200 x 600 x 1500 mm) and robust design make it adaptable to varied industrial environments.Q: What are the benefits of using a gasketed plate heat exchanger with automatic and manual controls?

A: A gasketed plate design allows quick access for inspection and maintenance. Automatic controls enhance efficiency and consistency, while manual options offer flexibility during special processing needs. Together, they enable high productivity and easy troubleshooting.Q: How is the liquid flow rate managed during operation?

A: The system accommodates a flow rate from 1 to 10 m/h, adjustable according to process requirements and product output. The flanged/clamped port connections support smooth flow management, optimizing pasteurization for batches up to 1000 L/h.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heat Exchanger Spares Parts Category

Heat Exchanger Cleaning Plate

Price 4800.00 INR / Unit

Minimum Order Quantity : 1 Set

Condition : New

Structure : Plate Heat Exchanger

Liquid Flow Rate : 12000 L/hr

Thickness : 2 mm

Gasketed Plate Heat Exchangers

Minimum Order Quantity : 25 Sets

Condition : New

Structure : Plate Heat Exchanger

Liquid Flow Rate : Any G/S

Thickness : 0.4 6 Millimeter (mm)

Metal Heat Transfer Plates

Price 465 INR

Minimum Order Quantity : 1 Piece

Condition : New

Structure : Other, Flat and corrugated plate

Liquid Flow Rate : 15 L/min

Thickness : 1 mm

Heat Exchanger Brazed Plate

Price 4966 INR / Number

Minimum Order Quantity : 1 Number

Condition : New

Structure : Brazed Plate, Other

Liquid Flow Rate : 2.5 m/hr 10 m/hr

|

DIVA ENGINEERING WORK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry