Heat Exchanger Refurbishment Service

MOQ : 2 Pieces

Heat Exchanger Refurbishment Service Specification

- Industries Served

- Chemical, Petrochemical, Power Generation, Pharmaceutical, Oil & Gas, Food Processing

- On-site Safety Measures

- Strictly implemented as per industry norms

- Environmental Compliance

- Follows standard industry environmental practices

- Documentation Provided

- Maintenance and Test Reports

- Heat Exchanger Type

- Shell & Tube, Plate, Finned Tube, and Custom Designs

- Refurbishment Work

- Cleaning, Repair, Re-tubing, Surface Treatment, Pressure Testing

- Turnaround Time

- Rapid service with minimum downtime (as per contract)

- Service Mode

- On-site / Off-site

- Type of Service

- Heat Exchanger Refurbishment Service

- Project Consultation

- Available on request

- Pressure Handling Capacity

- Up to 100 bar (as per unit specification)

- Duration of Service

- As per project requirement

- Replacement Parts Used

- OEM or Equivalent Quality

- Inspection & Diagnosis Offered

- Yes, including NDT and Hydro-testing

- Temperature Range

- Up to 600°C (as per specification)

- Service Location/City

- Pan India

- Emergency Support

- 24/7 emergency response provided

- After Sales Service

- Available

- Material Used

- Stainless Steel, Carbon Steel, Brass, Copper Alloys, Titanium

- Custom Refurbishment Solutions

- Offered based on client requirement

Heat Exchanger Refurbishment Service Trade Information

- Minimum Order Quantity

- 2 Pieces

- Supply Ability

- 300 Pieces Per Day

- Delivery Time

- 2-3 Days

About Heat Exchanger Refurbishment Service

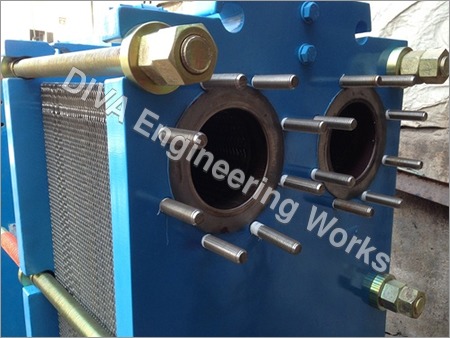

Refurbishment of Heat Exchanger

We are undertaking job work for the Refurbishment of Heat Exchangers (oil coolers, heaters, and condensers). With time, these equipment may see a loss in their effectiveness, hence causing higher cost and lower energy transfer. Diva Engineering Work provides complete refurbishment solutions for these equipment. As soon as we receive your heat exchanger, we start with the evaluation of its present condition. Thereafter suggestions are provided to you and then the modifications / improvements are made. With our expertise, we are able to ensure higher reliability in the Refurbishment of Heat Exchangers.

We are undertaking job work for the Refurbishment of Heat Exchangers (oil coolers, heaters, and condensers). With time, these equipment may see a loss in their effectiveness, hence causing higher cost and lower energy transfer. Diva Engineering Work provides complete refurbishment solutions for these equipment. As soon as we receive your heat exchanger, we start with the evaluation of its present condition. Thereafter suggestions are provided to you and then the modifications / improvements are made. With our expertise, we are able to ensure higher reliability in the Refurbishment of Heat Exchangers.

Advanced Inspection & Diagnosis

Our service incorporates state-of-the-art non-destructive testing (NDT) and hydro-testing procedures to accurately assess the condition of your heat exchanger. Clients receive comprehensive maintenance and test reports, ensuring transparency and facilitating informed maintenance decisions for improved operational reliability.

Customized Refurbishment Solutions

Understanding that every client and application has unique requirements, we provide tailored refurbishment strategies. This includes cleaning, re-tubing, repairs, and surface treatment, all executed with OEM or equivalent quality components to maximize exchanger performance and lifespan. Our consultation team is always available to design solutions specific to your needs.

Rapid Turnaround with Minimum Downtime

We recognize the value of time in critical operations. Our refurbishment processes are optimized for rapid completion, adhering strictly to contractually agreed schedules to keep your processes running smoothly. Additionally, we provide 24/7 emergency support for urgent issues, minimizing production loss.

FAQs of Heat Exchanger Refurbishment Service:

Q: How is the inspection and diagnosis of heat exchangers performed during refurbishment?

A: We utilize advanced non-destructive testing (NDT) and hydro-testing methods to evaluate the condition of heat exchangers. This thorough inspection helps identify internal or external faults, ensuring accurate assessment before refurbishment begins.Q: What documentation will be provided after the refurbishment service?

A: Upon completion, clients receive detailed maintenance and test reports. These documents outline inspection findings, steps taken during refurbishment, and results of all tests performed, serving as valuable records for future reference and compliance.Q: When and where can I access the Heat Exchanger Refurbishment Service?

A: Our service is available throughout Pan India and can be conducted on-site at your facility or off-site at our specialized service centers, scheduled as per project requirements and client convenience.Q: What is the general process for heat exchanger refurbishment?

A: The process typically includes inspection, cleaning, repair or re-tubing, surface treatment, and pressure testing. We use OEM or equivalent parts and high-quality materials, ensuring the refurbished unit meets or exceeds original specifications.Q: How does your service minimize operational downtime?

A: We prioritize rapid turnaround by adhering strictly to contracted timelines and deploying experienced teams for efficient execution. 24/7 emergency response services are available to address critical requirements and reduce production disruptions.Q: What types of heat exchangers and industries do you service?

A: We refurbish shell & tube, plate, finned tube, and custom-designed heat exchangers used in chemical, petrochemical, power generation, pharmaceutical, oil & gas, and food processing industries.Q: What are the main benefits of choosing your heat exchanger refurbishment service?

A: Benefits include extended equipment lifespan, improved efficiency, reduced operating costs, detailed documentation, environmental compliance, stringent safety practices, customized solutions, and ongoing after-sales support.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Refurbishment Service Category

Plate Heat Exchanger Refurbishment Service

Price Range 574.00 - 750.00 INR / Unit

Minimum Order Quantity : 1 Unit

|

DIVA ENGINEERING WORK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry